Share to

Chain conveyor

Email:

jimlee0218@huayucartonmachine.com

Wechat:

+86-15226701321

Still deciding? Get samples first, Contact US !

View similar products

Tag list

- Product Description

-

Product Introduction

The chain plate conveyor uses standard chain plates as the bearing surface and is powered by a motor reducer; We can use multiple parallel chain plates to make the chain plate conveyor wide and form a differential speed. By utilizing the speed difference of multiple chain plates, the multi column conveyor can be transformed into a single column conveyor without compression, thus meeting the requirements of single column conveyor for beverage labeling, filling, cleaning and other equipment. We can make the head and tail of the two chain plate conveyors into an overlapping mixed chain to make the bottle (can) body in a dynamic transition state, so that there is no material retention on the conveyor line, which can meet the pressure and pressure free conveying of empty bottles and solid bottles.

Overview of Chain Plate Conveyor

Chain plate conveyor chain plate specifications: The width of the straight chain plate is 63.5, 82.5, 101.6, 114.3, 152.4, 190.5, 254, 304.8; The width of the turning chain plate is 82.5, 114.3, 152.4, 190.5, 304.8

Characteristics of Chain Plate Conveyor

1. The conveying surface of the chain plate conveyor is flat and smooth, with low friction, and the transition of materials between conveyor lines is smooth. It can transport various materials such as glass bottles, PET bottles, and cans, as well as various bags and suitcases;

2. Chain plates come in a wide variety of materials and specifications, such as stainless steel and engineering plastics. They can be selected according to the requirements of the conveying materials and processes, and can meet the different needs of various industries;

3. The rack materials are divided into aluminum profiles, ordinary carbon steel, and stainless steel

4. Large conveying capacity, capable of carrying large loads, such as used in industries such as electric vehicles, motorcycles, generators, etc;

5. The conveying speed is accurate and stable, ensuring precise synchronous conveying;

6. Chain plate conveyors can generally be directly rinsed with water or soaked in water, making equipment easy to clean and meeting the hygiene requirements of the food and beverage industry;

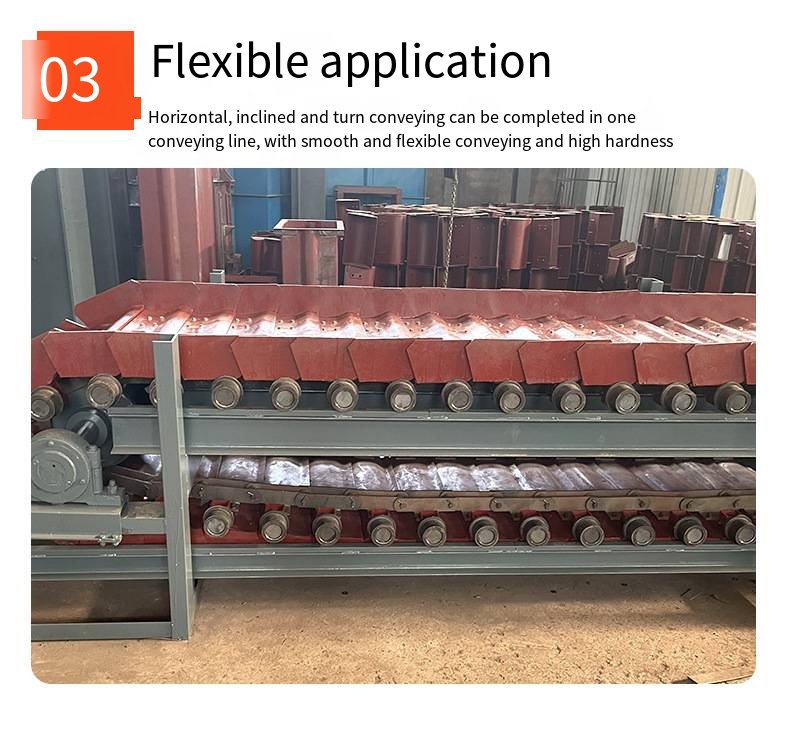

7. Flexible equipment layout. It can complete horizontal, inclined, and turning conveying on one conveyor line;

8. The device has a simple structure and is easy to maintain

About Us

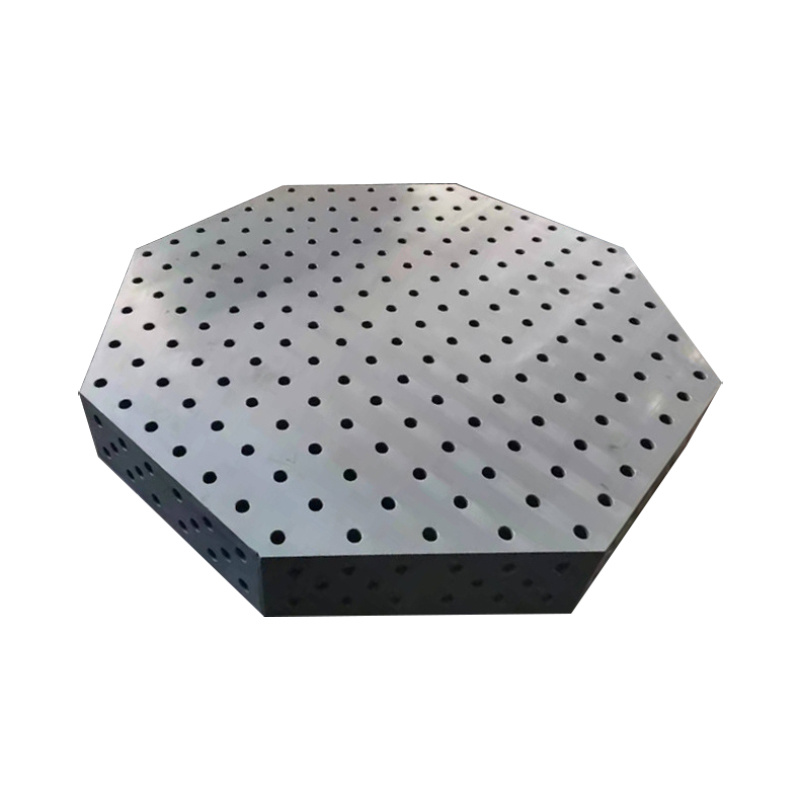

Botou Maosen Machinery Co., Ltd. focuses on the field of high-end machinery manufacturing, especially the research and development, production and sales of three-dimensional welding platform, cast iron processing platform, conveying equipment and environmental protection equipment and accessories. Using advanced design concept and technology, the selection of high-quality cast iron materials, precision machining, with high strength, high stability and corrosion resistance. Widely used in automotive manufacturing, aerospace, heavy machinery, machining, testing and measurement fields, to provide a variety of specifications and models to meet the needs of different application scenarios.

Certificate

Exhibition

Chain conveyor

Still deciding? Get samples first, Contact US !

Products Category

Tag list

Inquire Now

We will contact you within one working day. Please pay attention to your email.

Related Products

The 3D flexible welding platform enables you to achieve one-time clamping during the welding process

The 3D flexible welding platform enables you to achieve one-time clamping during the welding process

Welding platform fixtureWelding is crucial in many industries. The right tools are necessary for quality welds. A welding platform fixture is important for holding and positioning workpieces during welding. Benefits, types, and improvements of using a welding platform fixture will be discussed.Benefits of using a welding platform fixtureUsing a welding platform fixture provides a stable and secure platform for the workpiece, preventing any movement or vibrations during the welding process. This stability is crucial for achieving precise and high-quality welds.A welding platform fixture improves access to workpiece, making it easier for welder to reach all areas needing to be welded. This enhances weld quality and increases welding efficiency.Using a welding platform fixture helps reduce errors in welds by securely holding the workpiece in place. This ensures welds are done accurately, minimizing mistakes.Types of welding platform fixturesThere are several types of welding platform fixtures available, each designed for specific welding applications and workpiece configurations. Some common types include:1. Adjustable welding tables: These tables feature adjustable height and angle settings, allowing for versatile positioning of the workpiece during welding. They are ideal for welding projects that require flexibility and precision.2. Rotary welding fixtures: These fixtures rotate the workpiece during welding, allowing for 360-degree access to all sides of the workpiece. They are commonly used for cylindrical or round workpieces that need to be welded on all sides.3. Magnetic welding fixtures: These fixtures use magnets to hold the workpiece in place during welding, providing a strong and stable hold without the need for clamps or other fastening devices. They are suitable for flat or ferrous workpieces.4. Clamping welding fixtures: These fixtures use clamps or vices to hold the workpiece securely in place during welding. They are versatile and can be adjusted to accommodate different workpiece sizes and shapes.Improving the welding process with a welding platform fixtureUsing a welding platform fixture can significantly improve the overall welding process by enhancing the quality, efficiency, and accuracy of the welds. By providing a stable and secure platform for the workpiece, the fixture ensures that the welds are done precisely and consistently, resulting in high-quality welds that meet the required specifications.Additionally, the improved access to the workpiece allows the welder to work more effectively and efficiently, reducing the time and effort required to complete the welding project. This increased efficiency not only saves time and labor costs but also improves the productivity and profitability of the welding operation.

The 3D flexible welding platform enables you to achieve one-time clamping during the welding process