Share to

Cartridge filter

Email:

jimlee0218@huayucartonmachine.com

Wechat:

+86-15226701321

Still deciding? Get samples first, Contact US !

View similar products

Tag list

- Product Description

-

Product Introduction

The filter cartridge dust collector has a small footprint, large air processing capacity, fully automatic control, no need for dedicated personnel to supervise and operate, low initial investment, and low operating costs. It is an ideal dust removal equipment for small and medium-sized steelmaking enterprises.

The filter cartridge dust collector has the following characteristics

① The dust removal efficiency can reach above;

② Strong adaptability, able to handle different types of dust particles, and the processing capacity can be large or small;

③ The operation has great flexibility, and when the dust concentration in the inlet gas changes significantly, it will not have a significant impact on the dust removal efficiency;

④ Simple structure, flexible use, easy to recycle dry materials, and no sludge treatment.

Composition of filter cartridge dust collector

The components of the filter cartridge dust collector include the housing, filter bag, ash hopper, ash discharge device, bracket, and pulse cleaning system. When the dusty gas enters the dust collector through the air inlet, it will first hit the inclined partition in the middle of the air inlet, and the airflow will turn and flow into the ash hopper. At the same time, the airflow speed will slow down. Due to the effect of gravity settling, the coarse particles of dust in the gas will directly fall into the ash hopper, playing a role in pre dust collection. The airflow entering the ash hopper then bends upwards and passes through the filter bag with a metal frame inside. The dust is captured on the outer surface of the filter bag, and the purified gas enters the clean room at the upper part of the filter bag chamber, where it is collected and discharged through the air outlet pipe.

Working principle of filter cartridge dust collector

The filter cartridge dust collector has the characteristics of economic practicality, simple structure, easy installation, and convenient maintenance. Mainly used for dust collection in small dust collection points, this machine adopts polyester bags, with an inlet temperature of about 120 degrees Celsius and a dust removal effect of up to. It can provide temperature resistant and filter bag dust collectors for various purposes.

Workshop

About Us

Botou Maosen Machinery Co., Ltd. focuses on the field of high-end machinery manufacturing, especially the research and development, production and sales of three-dimensional welding platform, cast iron processing platform, conveying equipment and environmental protection equipment and accessories. Using advanced design concept and technology, the selection of high-quality cast iron materials, precision machining, with high strength, high stability and corrosion resistance. Widely used in automotive manufacturing, aerospace, heavy machinery, machining, testing and measurement fields, to provide a variety of specifications and models to meet the needs of different application scenarios.

Certificate

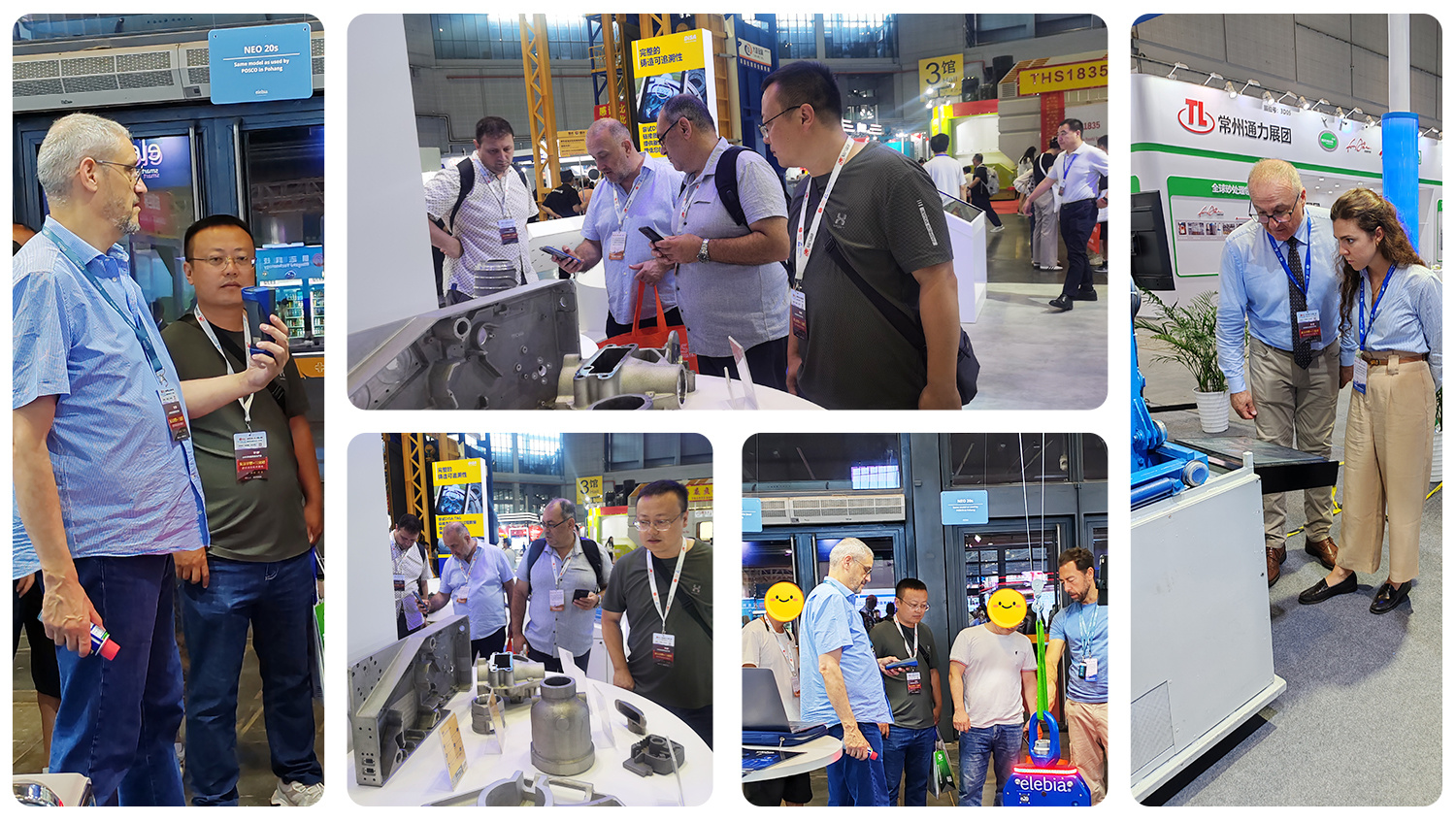

Exhibition

Cartridge filter

Still deciding? Get samples first, Contact US !

Products Category

Tag list

Inquire Now

We will contact you within one working day. Please pay attention to your email.

Related Products

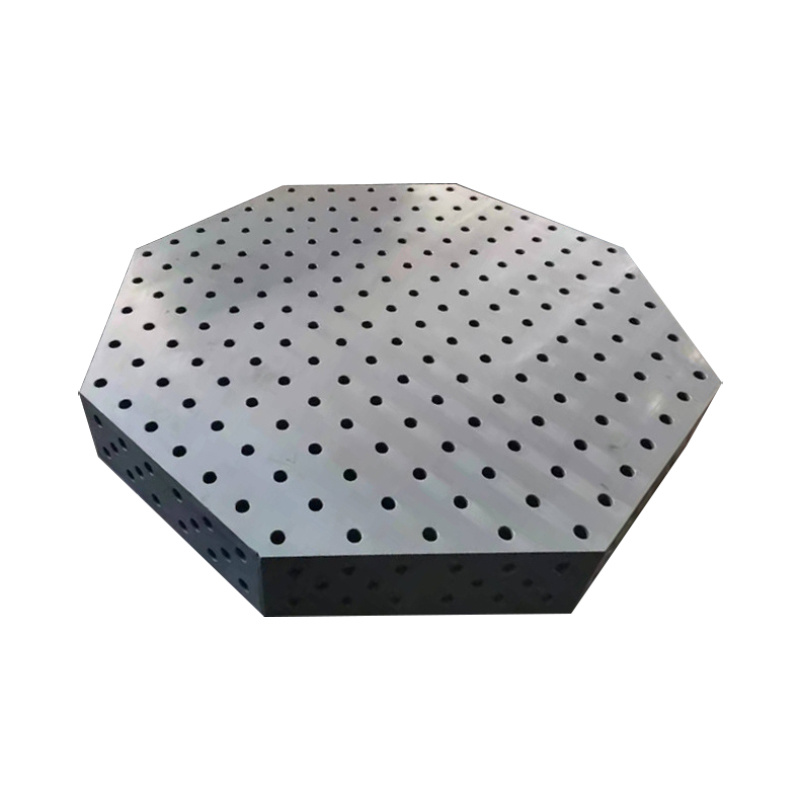

The 3D flexible welding platform enables you to achieve one-time clamping during the welding process

The 3D flexible welding platform enables you to achieve one-time clamping during the welding process

Welding platform fixtureWelding is crucial in many industries. The right tools are necessary for quality welds. A welding platform fixture is important for holding and positioning workpieces during welding. Benefits, types, and improvements of using a welding platform fixture will be discussed.Benefits of using a welding platform fixtureUsing a welding platform fixture provides a stable and secure platform for the workpiece, preventing any movement or vibrations during the welding process. This stability is crucial for achieving precise and high-quality welds.A welding platform fixture improves access to workpiece, making it easier for welder to reach all areas needing to be welded. This enhances weld quality and increases welding efficiency.Using a welding platform fixture helps reduce errors in welds by securely holding the workpiece in place. This ensures welds are done accurately, minimizing mistakes.Types of welding platform fixturesThere are several types of welding platform fixtures available, each designed for specific welding applications and workpiece configurations. Some common types include:1. Adjustable welding tables: These tables feature adjustable height and angle settings, allowing for versatile positioning of the workpiece during welding. They are ideal for welding projects that require flexibility and precision.2. Rotary welding fixtures: These fixtures rotate the workpiece during welding, allowing for 360-degree access to all sides of the workpiece. They are commonly used for cylindrical or round workpieces that need to be welded on all sides.3. Magnetic welding fixtures: These fixtures use magnets to hold the workpiece in place during welding, providing a strong and stable hold without the need for clamps or other fastening devices. They are suitable for flat or ferrous workpieces.4. Clamping welding fixtures: These fixtures use clamps or vices to hold the workpiece securely in place during welding. They are versatile and can be adjusted to accommodate different workpiece sizes and shapes.Improving the welding process with a welding platform fixtureUsing a welding platform fixture can significantly improve the overall welding process by enhancing the quality, efficiency, and accuracy of the welds. By providing a stable and secure platform for the workpiece, the fixture ensures that the welds are done precisely and consistently, resulting in high-quality welds that meet the required specifications.Additionally, the improved access to the workpiece allows the welder to work more effectively and efficiently, reducing the time and effort required to complete the welding project. This increased efficiency not only saves time and labor costs but also improves the productivity and profitability of the welding operation.

The 3D flexible welding platform enables you to achieve one-time clamping during the welding process