Share to

Multi tube smoke air cooler

Email:

jimlee0218@huayucartonmachine.com

Wechat:

+86-15226701321

Still deciding? Get samples first, Contact US !

View similar products

Tag list

- Product Description

-

Product Introduction

A multi tube air cooler for flue gas is a device used to cool high-temperature flue gas, typically used for cooling the flue gas generated during combustion processes in industrial production. It disperses the flue gas through multiple pipelines and conducts convective heat exchange with strong winds, thereby transferring the heat in the flue gas to the strong winds and achieving the cooling purpose of the flue gas.

A multi tube air cooler for flue gas usually consists of a forced fan and multiple pipes. After the flue gas is generated from the combustion equipment, it enters the multi tube air cooler through the pipes. At the same time, the fan blows strong wind into the multi tube air cooler, taking away the heat in the flue gas and achieving cooling of the flue gas. The flue gas in the multi tube air cooler will undergo sufficient heat exchange with the strong wind, causing a significant decrease in temperature in the flue gas. At the same time, the fan will discharge the cooled flue gas into the atmosphere, meeting the requirements of environmental emissions.

The advantages of multi tube air coolers for flue gas mainly include the following:

1. Efficient cooling: The multi tube air cooler disperses the flue gas through multiple pipes, increasing the contact area with strong winds and improving heat transfer efficiency, enabling rapid cooling of the flue gas.

2. Energy saving and environmental protection: The flue gas multi tube air cooler uses wind power as the heat exchange medium, which does not require additional energy consumption and saves energy costs; At the same time, the emission of flue gas after cooling treatment reduces environmental pollution.

3. Simple structure: The multi tube air cooler has a simple structure, is easy to install and maintain, and is also easy to control and operate, with a long service life.

4. Wide applicability: The multi tube air cooler for flue gas is suitable for cooling high-temperature flue gas generated in various industrial productions, such as boilers, furnaces, coal-fired equipment, etc.

Overall, the multi tube air cooler for flue gas is an effective industrial equipment that can help companies achieve cooling treatment of flue gas, reduce environmental pollution, and lower energy consumption. It is an energy-saving and environmentally friendly device. In future industrial production, flue gas multi tube air coolers are expected to be widely applied and promoted.

About Us

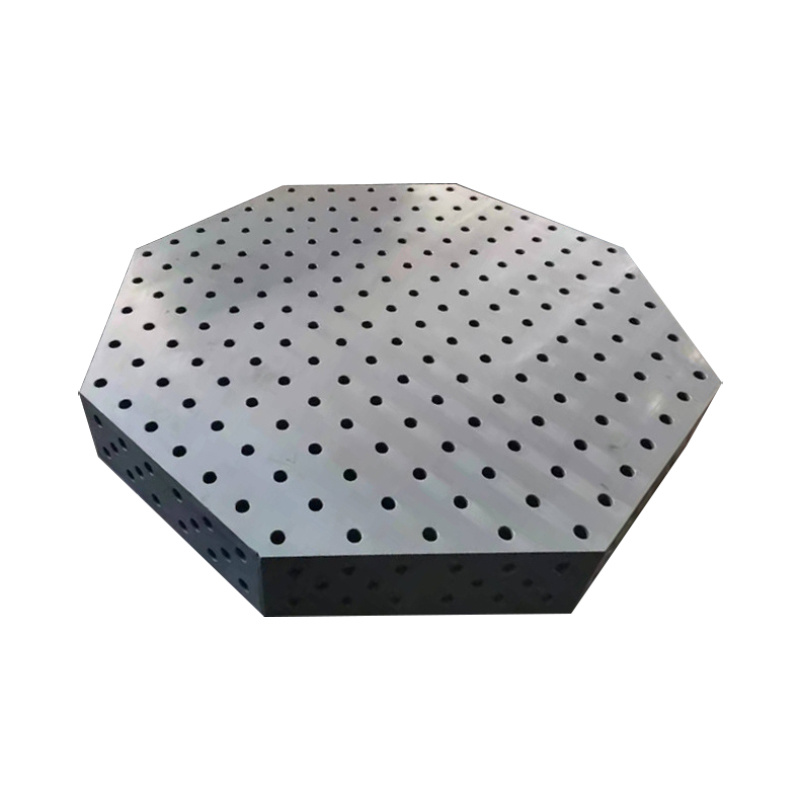

Botou Maosen Machinery Co., Ltd. focuses on the field of high-end machinery manufacturing, especially the research and development, production and sales of three-dimensional welding platform, cast iron processing platform, conveying equipment and environmental protection equipment and accessories. Using advanced design concept and technology, the selection of high-quality cast iron materials, precision machining, with high strength, high stability and corrosion resistance. Widely used in automotive manufacturing, aerospace, heavy machinery, machining, testing and measurement fields, to provide a variety of specifications and models to meet the needs of different application scenarios.

Certificate

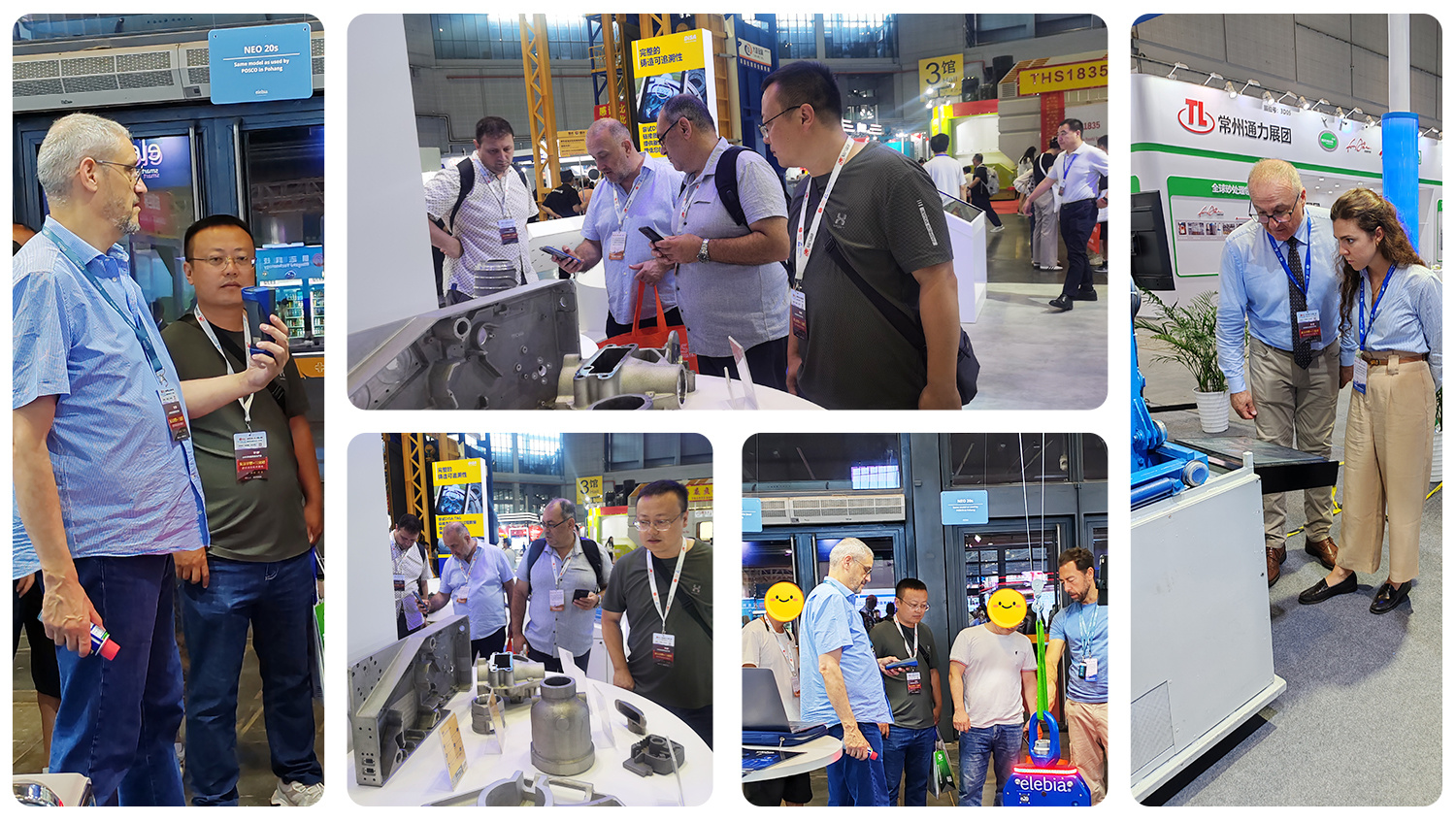

Exhibition

Multi tube smoke air cooler

Still deciding? Get samples first, Contact US !

Products Category

Tag list

Inquire Now

We will contact you within one working day. Please pay attention to your email.

Related Products

The 3D flexible welding platform enables you to achieve one-time clamping during the welding process

The 3D flexible welding platform enables you to achieve one-time clamping during the welding process

Welding platform fixtureWelding is crucial in many industries. The right tools are necessary for quality welds. A welding platform fixture is important for holding and positioning workpieces during welding. Benefits, types, and improvements of using a welding platform fixture will be discussed.Benefits of using a welding platform fixtureUsing a welding platform fixture provides a stable and secure platform for the workpiece, preventing any movement or vibrations during the welding process. This stability is crucial for achieving precise and high-quality welds.A welding platform fixture improves access to workpiece, making it easier for welder to reach all areas needing to be welded. This enhances weld quality and increases welding efficiency.Using a welding platform fixture helps reduce errors in welds by securely holding the workpiece in place. This ensures welds are done accurately, minimizing mistakes.Types of welding platform fixturesThere are several types of welding platform fixtures available, each designed for specific welding applications and workpiece configurations. Some common types include:1. Adjustable welding tables: These tables feature adjustable height and angle settings, allowing for versatile positioning of the workpiece during welding. They are ideal for welding projects that require flexibility and precision.2. Rotary welding fixtures: These fixtures rotate the workpiece during welding, allowing for 360-degree access to all sides of the workpiece. They are commonly used for cylindrical or round workpieces that need to be welded on all sides.3. Magnetic welding fixtures: These fixtures use magnets to hold the workpiece in place during welding, providing a strong and stable hold without the need for clamps or other fastening devices. They are suitable for flat or ferrous workpieces.4. Clamping welding fixtures: These fixtures use clamps or vices to hold the workpiece securely in place during welding. They are versatile and can be adjusted to accommodate different workpiece sizes and shapes.Improving the welding process with a welding platform fixtureUsing a welding platform fixture can significantly improve the overall welding process by enhancing the quality, efficiency, and accuracy of the welds. By providing a stable and secure platform for the workpiece, the fixture ensures that the welds are done precisely and consistently, resulting in high-quality welds that meet the required specifications.Additionally, the improved access to the workpiece allows the welder to work more effectively and efficiently, reducing the time and effort required to complete the welding project. This increased efficiency not only saves time and labor costs but also improves the productivity and profitability of the welding operation.

The 3D flexible welding platform enables you to achieve one-time clamping during the welding process